Fire Protection Requirements in the Aviation Industry

The requirements for materials in aircraft construction are among the strictest in the world. In addition to weight reduction and design aspects, fire protection plays a central role. Aircraft cabin materials must not emit toxic gases or ignite easily in the event of fire. This is where innovative solutions like BRANOflame come into play. The flame-retardant paper meets the high safety standards of the aviation industry while offering great flexibility in various manufacturing processes – a key advantage for complex interior applications.

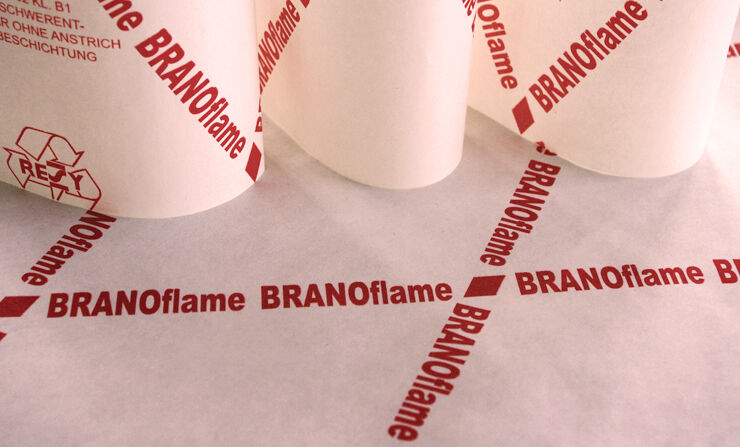

BRANOflame – the High-Performance Flame-Retardant Paper from BRANOpac

BRANOflame is a specially developed flame-retardant paper designed with a patented functional layer that ensures maximum fire resistance. It is based on a multi-layer structure in which the flame protection effect is permanently integrated into the paper. As a result, the protective function remains intact even after further processing, lamination, or coating. The material is halogen-free, silicone-free, and low-emission – making it both environmentally friendly and technically efficient. BRANOflame is available in different grammages and variants and can be customized to meet individual customer requirements.

Application of BRANOflame in Decorative Veneers for Exclusive Aircraft Kitchens

A prime example of BRANOflame in use is its integration into decorative veneers used in the interiors of private jets. Here, the flame-retardant paper is embedded within the veneer structure, providing the surface with flame-resistant properties without affecting its luxurious appearance or feel. In the elegant kitchen areas of private jets, BRANOflame ensures maximum safety combined with premium design. Manufacturers benefit from easy processing and the ability to realize even sophisticated design concepts in compliance with fire safety regulations.

Further Areas of Application for BRANOflame in Fire Protection

Beyond aviation, BRANOflame is also used in numerous other industries. In the rail sector, public building interiors, electrical engineering, and machine enclosures, the paper provides reliable fire protection at low weight. Thanks to its versatile processing properties – such as laminating, coating, or pressing – it can be seamlessly integrated into existing production processes. This makes BRANOflame not only a safety product but also a real efficiency factor in industrial applications.

Advantages of BRANOflame for the Aviation Industry

- Reliable fire protection: meets international safety standards

- Lightweight: ideal for aviation-specific requirements

- Design flexibility: suitable for use in high-end surface materials

- Sustainability: halogen- and silicone-free, environmentally responsible

- Cost efficiency: durable, flexible, and easy to process

This combination makes BRANOflame a preferred material for manufacturers seeking to combine top-level safety standards with aesthetics and sustainability.

Conclusion – Safety and Quality United with BRANOflame

BRANOflame demonstrates how modern fire protection and sophisticated design can work hand in hand. The flame-retardant paper from BRANOpac delivers safety, versatility, and environmental compatibility – setting new standards in the aviation industry. Whether in private jets, train interiors, or architectural design, BRANOflame provides safety wherever it matters most.

![[Translate to Englisch:] Florence Lachat [Translate to Englisch:] Florence Lachat](/fileadmin/_processed_/4/7/csm_florence_lachat_f8da7b26cc.png)