Caoutchouc

What is caoutchouc?

Elastic polymers – from which rubber is made – are known as caoutchouc. There are two types of caoutchouc: synthetic caoutchouc, which is produced based on petrochemical raw materials, and natural caoutchouc, which is mainly obtained from the white sap of the caoutchouc tree.

By reacting with sulfur, caoutchouc turns into rubber. This process is known as vulcanization. When this rubber compound, is heated to 145°C (293.0°F), it becomes sticky. At over 170°C (338.0°F) it dissolves and finally burns with a still flame.

Excellent release properties

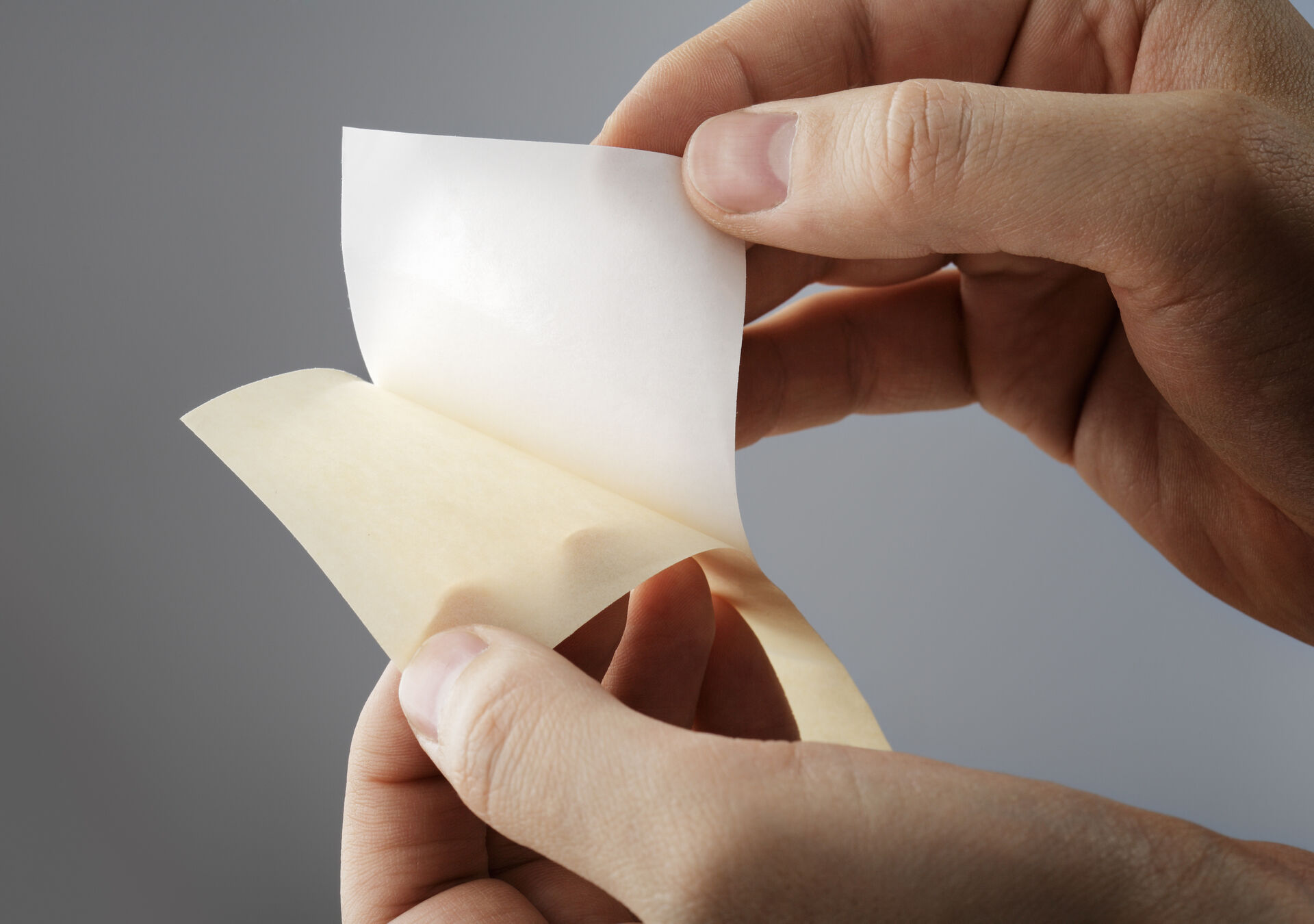

Caoutchouc is also processed into, for example, sealing profiles. Liquid rubber has to be poured into molds, in order to take on the desired sealing form. To prevent the sticky mass from sticking to the molds, a release paper is often placed between the molds and the mass.

BRANOperl is a paper coated on one or both sides, which can be used excellently as a release paper The paper has good heat resistance and is available in a bleached or unbleached version. Due to its excellent release properties, it reliably prevents strips or sheets of material from sticking together or to other materials.

Advantages of our release paper

- Environmentally friendly material

- Excellent release properties

- Clean and econimic operating

- Development of customized solutions possible

- Easy to dispose

- Non-hazardous material

- BRANOpac is certified according to ISO 9001 and ISO 14001

A release paper with numerous possible applications

- In the composites industry to facilitate production, e.g. with the thermal pressing of laminates.

- In the medical sector as an intermediate layer for self - adhesive dressing materials, e.g. for feminine hygiene products.

- In the print industry as transfer paper in silkscreen printing and tampon processes.

- For office supplies as a release paper for household foil, labels and stickers.

- In technical sectors as an intermediate layer for liquid bitumen, for lining molds, as release paper for the production of rubber and raw rubber.

- In textile printing as transfer paper and release paper for thermal fixing.

- In film printing as release paper.

- In the plastics industry as transfer paper for hot melt adhesives.

- As a trailing paper for web-shaped materials.

- As scratch protection for metal and wooden fronts in the furniture industry.

We would be happy to advise you – get in touch with us! You will find the contact details on the right. You can also find more information about BRANOperl at www.branopac.com.

You can also purchase BRANOperl in our online shop at www.branoshop.com.