Extrusion

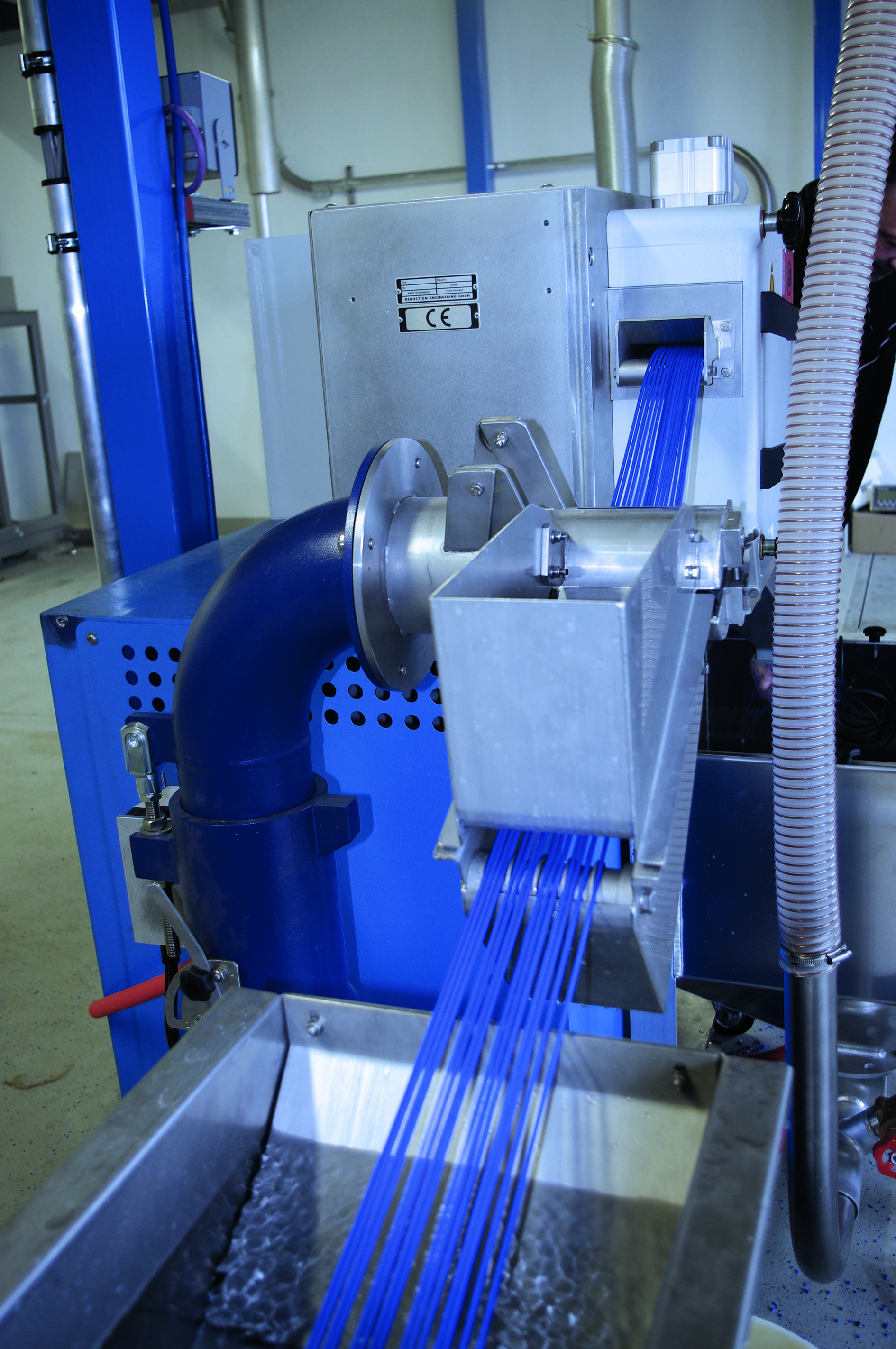

The process of extrusion involves plastics or other thermosetting materials, being squeezed through a nozzle in a continuous procedure.

A distinction is made between two types of extruders: processing and compounding extruders. The processing extruder presses the mass into a certain shape. Then the compounding extruder is used to add active ingredients to the mass in order to obtain additional properties in the end product. Typical properties are coloring, UV protection, flame retardant effect, antistatic and corrosion protection.

Extruders can be used for the following fields of application:

- Plastics industry

- Chemical industry

- Food industry

- Color industry

- Pharmaceutical Industry

BRANOpac has three so-called planetary roller extruders. The core of this device is formed by the central spindle, roller cylinder, rotating planetary spindles and internally toothed guide bush. The extruder components and their arrangement ensure excellent temperature control as well as very good dispersion and homogenization. All polyolefins, as well as polystyrene to a limited extend, can be processed in the temperature range from 20 ° C up to 260 ° C with the planetary roller extruders at BRANOpac.

For more information, visit www.branopac.com.