Silicone vs. Quilon parchment papers

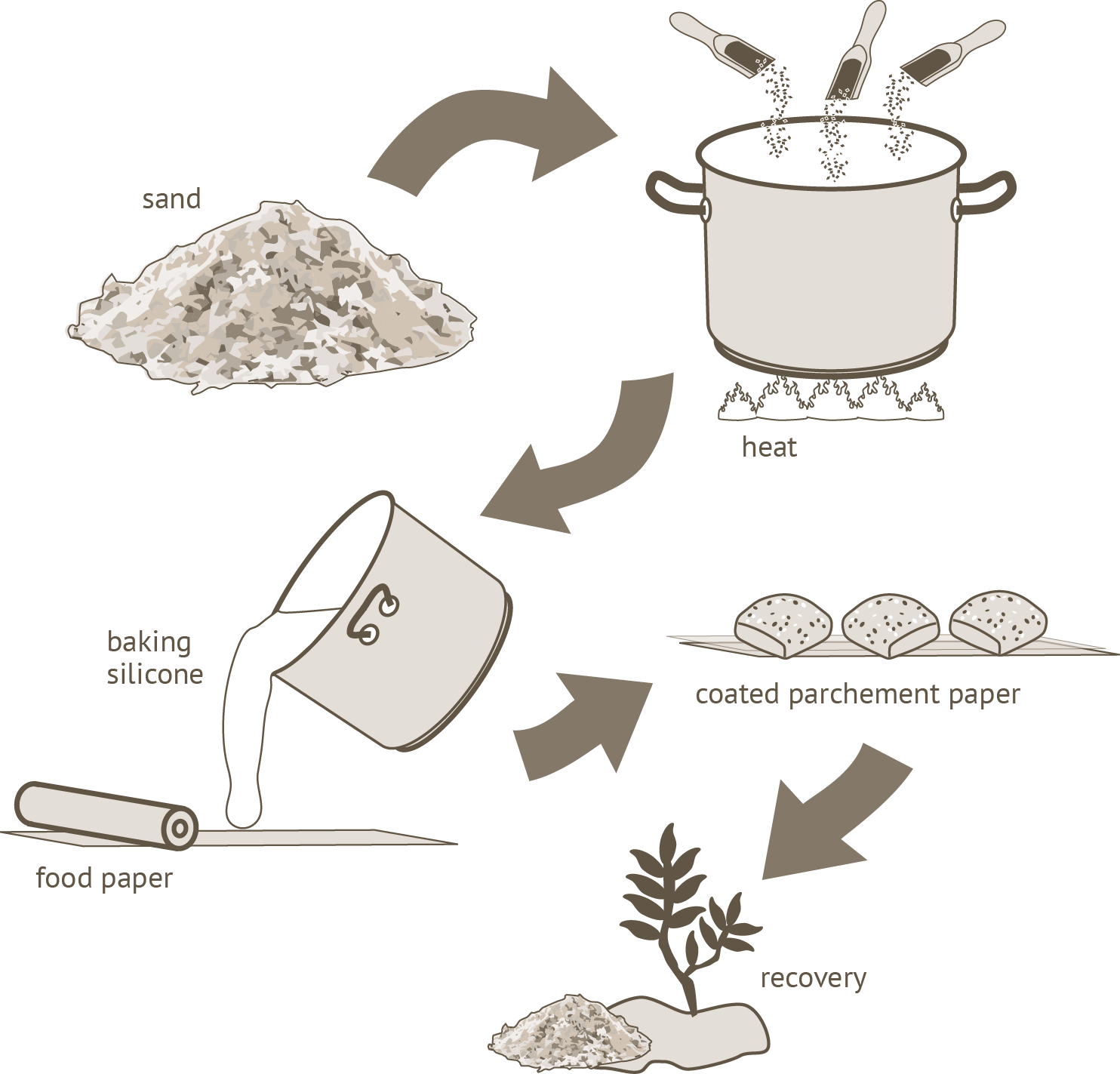

Parchment papers can be either coated with silicone or with quilon. While silicone is a non-organic natural product found in sand, quartz and rock, Quilon is a chemical that contains the heavy metal chromium. When Quilon is incinerated, it becomes a potential toxic hazard that can cause multiple health issues. Silicone, on the other hand, is non-toxic when incinerated. Besides, it is abiotically degradable and dissolves in nature. Further, BRANOpac uses a special baking silicone to coat the baking paper.

Although parchment paper coated with Quilon is less costly than the one coated with silicone, the cost advantage does not pay off in the end since Quilon-coated parchment paper can only be used once. In contrast to that, silicone-coated parchment paper can be used multiple times. Moreover, Quilon papers break down fast under heat treatment whereas silicone papers display a high heat resistance. The latter is ovenproof up to 220°C which equals 428°F.

The quality of the two coatings also differs with regard to greaseproof- and release effects. Parchment paper coated with silicone not only disposes of greater greaseproof effects than Quilon-coated parchment paper, its release effects are also greater.

In addition to that, silicone parchment paper does not alter the taste of food during baking.

Parchment paper coated with silicone is the traditional choice of professionals in Europe and Asia whereas Quilon-coated parchment paper usually is not used in Europe.

For further information about our baking silicone-coated parchment papers visit our website www.blechrein.de/en or www.branopac.com/en/branofood for B2B requirements. In addition, you can purchase our siliconized baking papers at our onlineshop.