Extruder

An "extruder" is a special device to transport solid to viscous mass. The mass is pressed from an opening under constant temperature and pressure.

There are processing and treatment extruders. Use of processing extruders serves the purpose of pressing the mass to be processed into a specific shape.

The treatment extruder mixes effective substances into the mass to be processed to achieve additional characteristics in the final product.

Typical characteristics are, in addition to colouration, UV protection, flame-retardant effect, anti-static properties and corrosion protection.

Extruders are used in the

- plastics industry

- chemicals industry

- foodstuffs industry

- dye industry

- pharmaceutics industry

The production method is called extrusion.

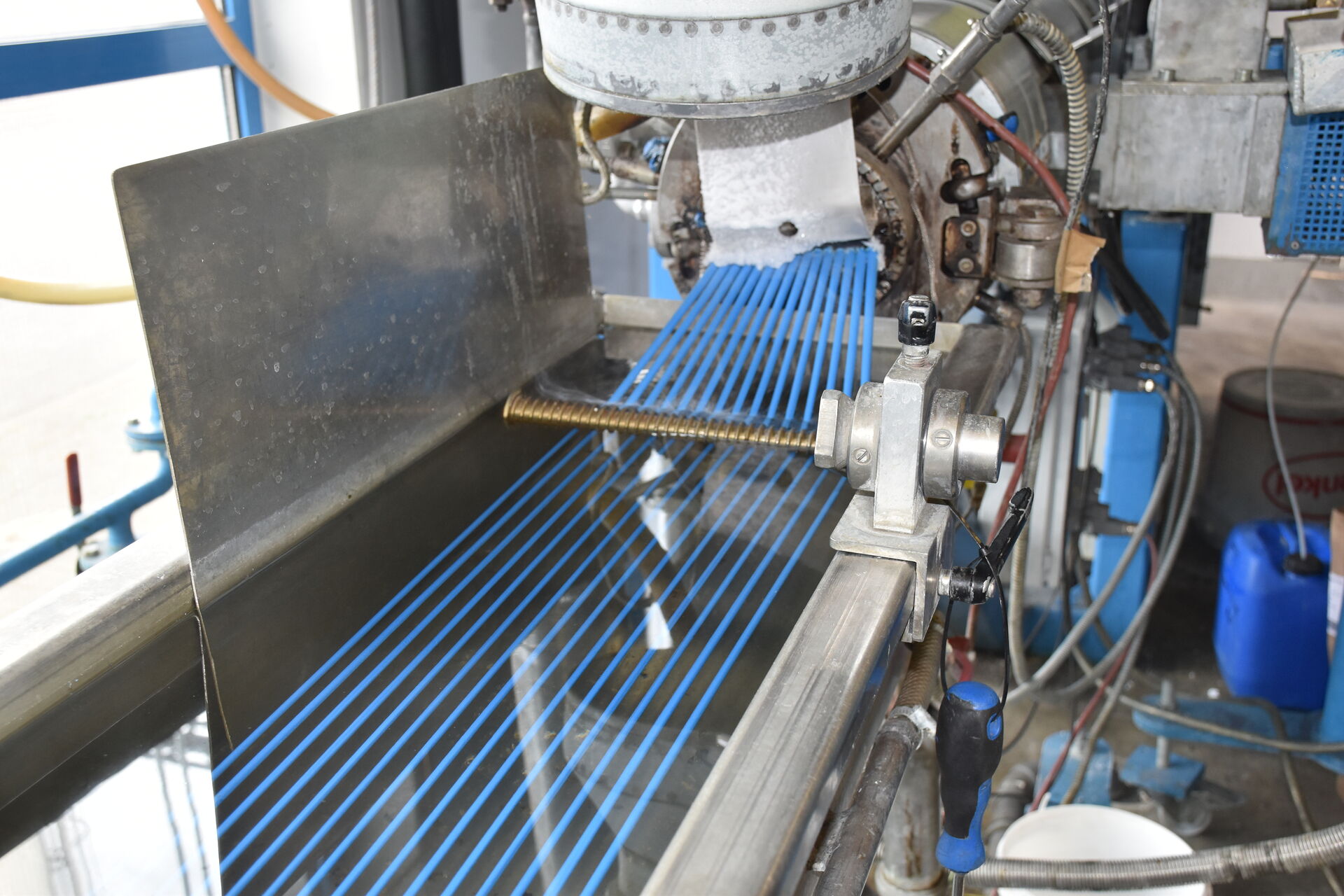

BRANOpac has three so-called planetary roll extruders. Central spindle, roll cylinder, rotating planetary spindles and internally interlocked guide sockets form the core of the planetary roll extruder.

Both the extruder components and their alignment ensure great temperature control and inspection, as well as very good dispersion and homogenisation.

The planetary roll extruders at BRANOpac permit processing of any polyolefins and, with limitations, polystyrene. BRANOpac offers master batch production as a service. According to customer requirements or in the scope of development between customers and BRANOpac, master batches are produced in contracted batch procedures.

You will find more information at www.branopac.com.