The challenge in toy manufacturing: precision and safety when ironing beads

In toy manufacturing, all materials used must meet the industry's strict safety requirements. This is particularly true for craft and creative products such as ironing beads, where no residues may occur and handling for end users—especially children—must remain safe and simple.

When ironing beads, the paper must not stick or damage the surface. Therefore, the release paper must be heat-resistant, dimensionally stable, and clean-releasing without residue. Many standard papers fail here because they warp or adhere at high temperatures. BRANOperl, by contrast, was developed precisely for these requirements and ensures consistent quality—even under repeated heat exposure.

BRANOperl release paper – engineered for maximum heat resistance and clean release

BRANOperl is a high-quality, coated release paper with excellent thermal and mechanical properties. Its uniform surface and special coating prevent plastics from sticking and ensure a clean release after heating.

Thanks to its high temperature resistance, BRANOperl remains dimensionally stable even with multiple uses. These properties make it attractive not only for toy manufacturing but also for many industrial processes in which materials are processed or bonded under heat. The result: clean processing, reliable outcomes, and maximum application safety.

BRANOperl in ironing bead production at a toy manufacturer

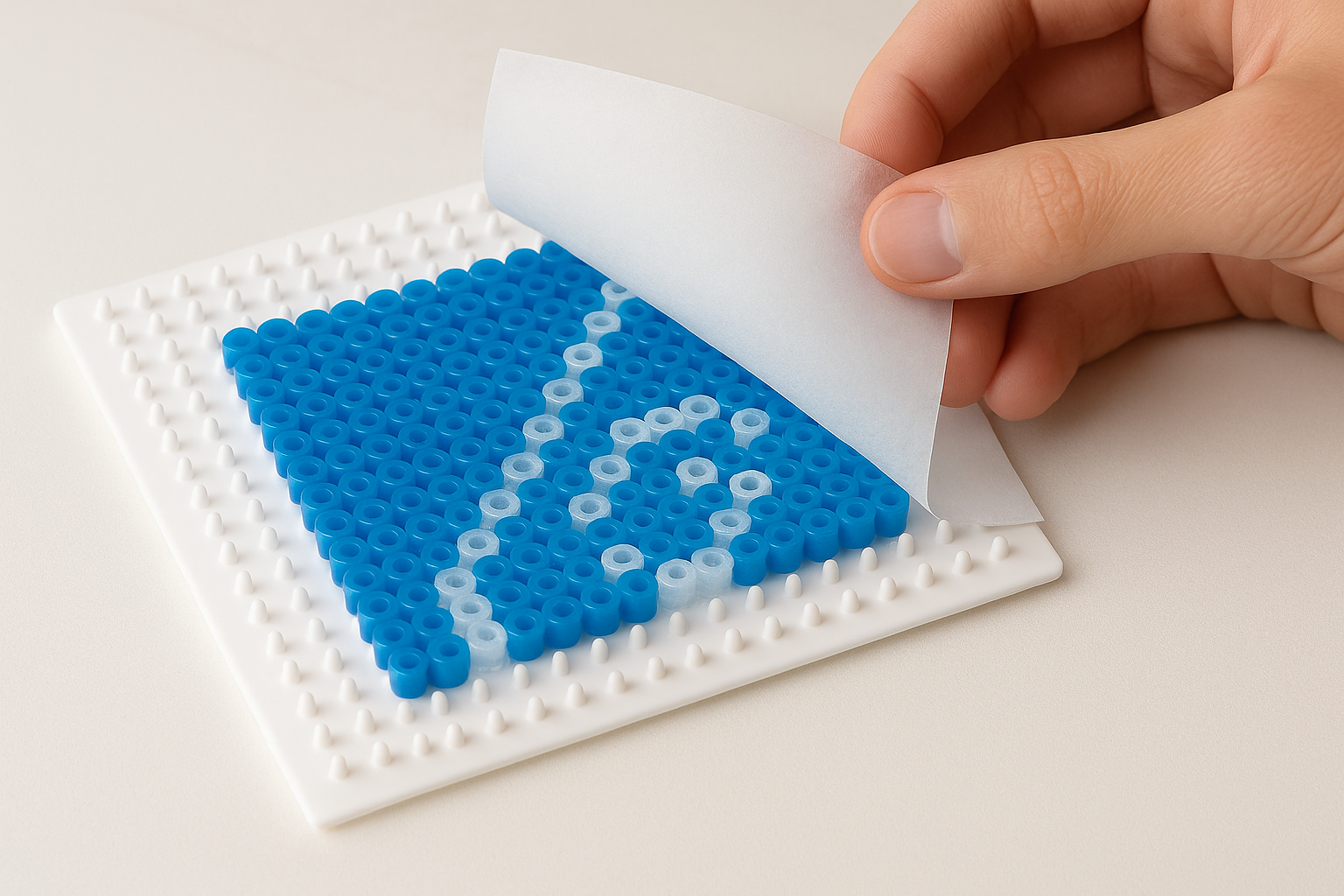

A leading toy manufacturer successfully uses BRANOperl as release paper in the production of ironing bead sets. The paper acts as a protective layer between the arranged beads and the iron.

During fusing, BRANOperl prevents plastic from sticking to the iron and distributes heat evenly across the surface. After cooling, the paper can be removed easily and without residue—leaving no marks or damage.

For end users, this means clean results, safe handling, and longer accessory life. Manufacturers benefit from higher process reliability and a lower scrap rate.

Further use cases for BRANOperl release paper

Beyond classic ironing bead applications, BRANOperl is used in many other areas of the toy and creative industries, including:

- Craft and creative kits where BRANOperl serves as a separating layer between heat-sensitive materials.

- Packaging solutions where delicate surfaces are protected from heat, adhesives, or friction by BRANOperl.

- Industrial assembly processes that require clean separation layers between plastic or adhesive components.

In all these applications, BRANOperl convinces with its combination of heat resistance, dimensional stability, and optimal release properties—a quality feature that meets the high demands of professional manufacturers.

Conclusion: BRANOperl as a reliable partner for the toy industry

With BRANOperl, BRANOperl offers a solution tailored to the requirements of toy production. The release paper ensures safe, clean, and reproducible results—from craft kits to series production.

Its consistently high quality and wide range of applications make BRANOperl a reliable partner for manufacturers who prioritize efficiency, product safety, and high-quality processing.

![[Translate to Englisch:] florence_lachat [Translate to Englisch:] Florence Lachat](/fileadmin/_processed_/4/7/csm_florence_lachat_f8da7b26cc.png)